TSMC's Semiconductor Manufacturing Dominance: How Taiwan Became the Silicon Kingmaker

With 54% of global foundry market share and exclusive production of the world's most advanced chips, TSMC has become the most critical company in the semiconductor supply chain. Discover how this Taiwanese giant achieved unprecedented dominance.

In the global semiconductor industry, one company stands above all others: Taiwan Semiconductor Manufacturing Company (TSMC). This Taiwanese foundry doesn't just lead the market—it defines it. With a market capitalization exceeding $500 billion and manufacturing capabilities that no competitor can match, TSMC has become the silent giant powering the world's technology.

From Apple's iPhone processors to NVIDIA's AI accelerators, TSMC manufactures the chips that power our digital world. But how did a company founded in 1987 in Taiwan become so dominant that it holds the entire tech industry in its hands?

TSMC by the Numbers

Market Dominance

Global foundry market share

Advanced node market share

Annual revenue (2024)

Global customers

Technology Leadership

The Rise of TSMC: From Startup to Silicon Kingmaker

The Foundry Model Revolution

When Morris Chang founded TSMC in 1987, the semiconductor industry operated on an Integrated Device Manufacturer (IDM) model—companies designed and manufactured their own chips. Chang's revolutionary idea was the "pure-play foundry" model: focus solely on manufacturing chips designed by other companies.

Traditional IDM Model

- • Design + Manufacturing

- • High capital requirements

- • Limited customer base

- • Technology development risk

TSMC's Foundry Model

- • Manufacturing focus only

- • Shared R&D costs

- • Multiple customers per node

- • Economies of scale

Key Milestones in TSMC's Dominance

Foundation

Morris Chang establishes TSMC with government backing and Philips partnership

IPO Success

Goes public on Taiwan Stock Exchange, raising capital for expansion

Apple Partnership

Begins manufacturing Apple's A-series processors, securing massive volumes

7nm Leadership

First to mass-produce 7nm chips, leaving Intel behind

3nm Production

Achieves world's first 3nm mass production, cementing technological leadership

Unmatched Technology Leadership

Process Node Comparison

R&D Investment

What Makes TSMC's Technology Superior

EUV Mastery

Advanced extreme ultraviolet lithography implementation with highest yields

Process Optimization

Continuous improvement in power, performance, and area (PPA) metrics

Yield Excellence

Industry-leading manufacturing yields reducing customer costs

The TSMC Customer Ecosystem

Major Customers by Revenue

Why Customers Choose TSMC

Technology Leadership

Access to most advanced manufacturing processes

Manufacturing Excellence

Highest yields and quality in the industry

Capacity Scale

Ability to handle massive production volumes

Customer Trust

No competition with customers (pure-play model)

Ecosystem Support

Comprehensive design and packaging services

Innovation Partnership

Co-development of next-generation technologies

Geopolitical Implications of TSMC's Dominance

The Taiwan Advantage

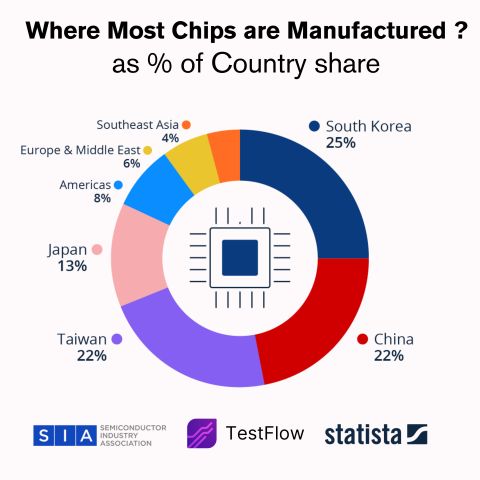

TSMC's dominance has made Taiwan the most critical link in the global semiconductor supply chain. This concentration of advanced manufacturing in one geopolitical location creates both opportunities and risks.

Strategic Advantages

- • Highly skilled engineering workforce

- • Strong government support for semiconductors

- • Established supply chain ecosystem

- • Cultural focus on manufacturing excellence

- • Proximity to key Asian markets

Geopolitical Risks

- • US-China technology tensions

- • Taiwan's complex political status

- • Natural disaster vulnerability

- • Supply chain concentration risk

- • Export control restrictions

Global Response: Building Alternative Capacity

United States

CHIPS Act: $52B investment to rebuild domestic semiconductor manufacturing

European Union

EU Chips Act: €43B to achieve 20% global production by 2030

China

Massive state investment in domestic foundry capabilities

Future Challenges and Opportunities

Challenges

Physics Limitations

Approaching fundamental limits of silicon scaling

Rising Costs

Each new node requires exponentially higher investment

Geopolitical Pressure

Forced to balance competing national interests

Talent Competition

Global shortage of semiconductor engineers

Opportunities

AI Demand Growth

Explosive growth in AI chip requirements

Advanced Packaging

New revenue streams in chiplet integration

Global Expansion

Building fabs in US, Japan, and Europe

New Technologies

Leading development of next-gen materials and processes

TSMC's Enduring Dominance

TSMC's rise to dominance wasn't accidental—it was the result of visionary leadership, relentless focus on manufacturing excellence, and the foresight to bet on the foundry model when others were skeptical. Today, the company's technological leadership and manufacturing scale create a competitive moat that competitors struggle to cross.

While geopolitical tensions and the push for supply chain diversification pose challenges, TSMC's head start in advanced manufacturing, combined with its massive R&D investments and customer relationships, position it to maintain leadership for the foreseeable future.

For the global technology industry, TSMC represents both an enabler and a single point of failure. Understanding this company's capabilities, strategies, and limitations is crucial for anyone involved in semiconductor design, manufacturing, or policy-making.

Validate Your Chips with Confidence

Whether your chips are manufactured by TSMC or other foundries, comprehensive validation ensures they meet performance and reliability requirements. TestFlow's AI-powered platform provides the testing capabilities you need.