8 Layers of the Semiconductor Industry: Inside the $1 Trillion Chip Ecosystem

From raw materials to final systems, the semiconductor industry is a global relay race where each layer is critical and each player irreplaceable. Discover the 8 essential layers that power our digital world.

The semiconductor industry isn't dominated by a single company—it's a deep, interconnected stack of specialized players, each mastering a critical piece of the chip creation puzzle. From the pure silicon wafers that form the foundation to the complex systems that end up in your smartphone, this $1 trillion ecosystem represents one of humanity's most sophisticated supply chains.

Understanding these 8 layers is crucial for anyone working in technology, as disruption in any single layer can ripple across the entire global tech ecosystem. Let's explore how this intricate machine works.

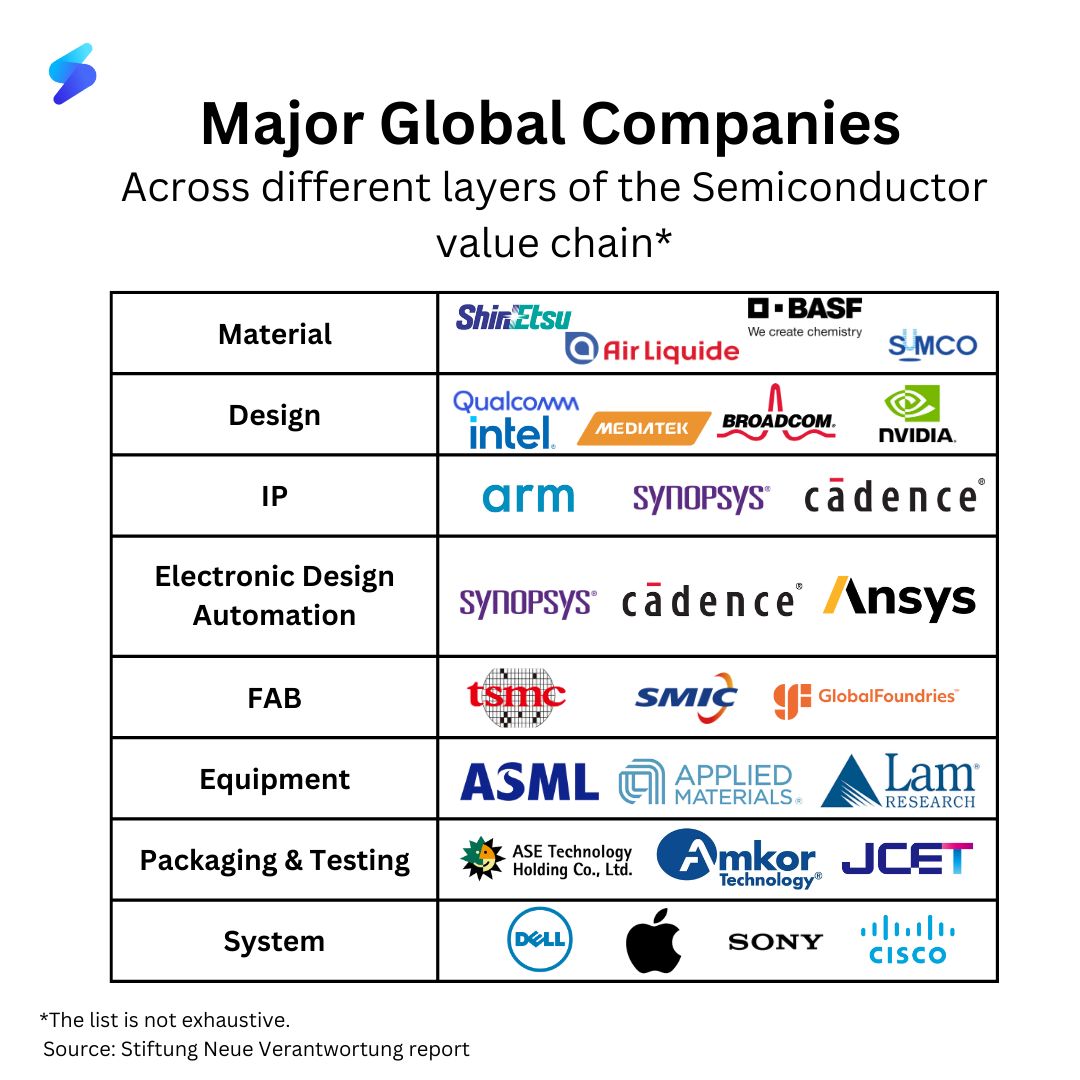

The Semiconductor Industry Stack

System Companies

Final products you use daily

Apple

iPhones, Macs, iPads

Dell

PCs, Servers

Sony

PlayStation, TVs

Cisco

Networking equipment

These companies integrate chips into complete systems that consumers and businesses use. They drive demand for semiconductors and define performance requirements.

Packaging & Testing (OSAT)

Connecting dies to the real world

ASE Group

World's largest OSAT

Amkor

Advanced packaging

JCET

Chinese OSAT leader

SPIL

Memory packaging

OSATs handle the final assembly, packaging, and testing of semiconductor chips before they ship to customers. They ensure chips work correctly and can survive real-world conditions.

Equipment Vendors

Machines that print at nanometer scale

ASML

EUV lithography

Applied Materials

Deposition, etch

Lam Research

Plasma etching

KLA

Process control

These companies build the ultra-complex machines that fabricate chips. ASML's EUV scanners cost $200M each and are essential for advanced nodes.

Foundries & IDMs

The most complex factories in the world

TSMC

62% foundry share

Samsung

Memory + foundry

GlobalFoundries

Mature nodes

Intel

IDM + foundry

Foundries manufacture chips designed by other companies, while IDMs design and manufacture their own. These fabs cost $20B+ and take 3-5 years to build.

EDA Tools

The invisible engines of chip creation

Synopsys

Design, verification

Cadence

Analog, digital

Siemens EDA

Verification, test

TestFlow

AI validation

EDA tools enable engineers to design, simulate, and verify billion-transistor chips. Without these software platforms, modern chip design would be impossible.

IP Cores

Reusable logic blocks and processor cores

Arm

CPU architectures

Imagination

GPU cores

Rambus

Memory interfaces

CEVA

DSP cores

IP companies create reusable building blocks that chip designers license and integrate into their SoCs. Arm's CPU cores power 95% of smartphones.

Fabless Design Companies

The brains behind the architecture

Qualcomm

Mobile SoCs

NVIDIA

GPUs, AI chips

AMD

CPUs, GPUs

Broadcom

Networking, RF

Fabless companies focus purely on chip design and outsource manufacturing to foundries. This model enables innovation without massive capital investment.

Raw Materials

Where it all begins—chemicals, wafers, gases

Shin-Etsu

Silicon wafers

BASF

Chemicals

Air Liquide

Process gases

Sumco

Silicon substrates

Materials companies provide the ultra-pure silicon wafers, chemicals, and gases that make chip manufacturing possible. Quality here determines yield downstream.

Critical Interdependencies

How the Layers Connect

Material Quality → Chip Yield

Ultra-pure silicon wafers and chemicals directly impact manufacturing yield rates

EDA Tools → Design Complexity

Advanced software enables billion-transistor designs that would be impossible manually

Equipment Innovation → Process Nodes

ASML's EUV technology enables 7nm, 5nm, and 3nm manufacturing

System Demand → Innovation Cycles

Consumer electronics drive requirements that cascade through all layers

Single Points of Failure

Critical Bottlenecks

- • ASML: Only supplier of EUV lithography

- • TSMC: 62% of foundry capacity

- • Taiwan: 63% of global chip production

- • Shin-Etsu: Major silicon wafer supplier

Risk Mitigation

- • Geographic diversification efforts

- • Strategic inventory management

- • Alternative supplier development

- • Government policy support

Economic Impact by Layer

Market Size by Layer (2024)

Growth Trends

AI/ML driving system demand

Equipment CAGR (2024-2030)

Overall semiconductor CAGR

Future Evolution of the Stack

Emerging Trends

New Layer: AI Validation

AI-powered validation and testing platforms are becoming a distinct layer, automating complex chip validation processes.

Chiplet Ecosystem

Modular chip architectures are creating new players focused on chiplet design and integration.

Consolidation vs. Specialization

Consolidation Trends

- • Foundry market concentrating in TSMC

- • EDA dominated by 3 major players

- • Equipment consolidation around leaders

- • Vertical integration by system companies

New Specializations

- • AI-specific chip architectures

- • Edge computing optimizations

- • Quantum-classical hybrid systems

- • Sustainability-focused processes

The Intricate Machine of Innovation

The semiconductor industry's 8-layer structure represents one of humanity's most complex and sophisticated supply chains. Each layer depends on the others, creating a delicate ecosystem where innovation in one area can transform entire industries.

Understanding these interdependencies is crucial for anyone working in technology. A disruption in materials can affect chip yields; advances in EDA tools enable new architectures; equipment breakthroughs unlock smaller process nodes; and system demand drives innovation throughout the stack.

As we move toward an AI-driven future, this 8-layer structure continues to evolve, with new specializations emerging and traditional boundaries blurring. The companies that master multiple layers—or create entirely new ones—will shape the next chapter of technological progress.

Optimize Your Layer in the Stack

Whether you're designing chips, manufacturing them, or validating their performance, TestFlow's AI-powered platform helps optimize your role in the semiconductor ecosystem. Join the companies revolutionizing chip validation.