2.5D vs 3D ICs: The Difference Between Horizontal and Vertical Integration

As Moore's Law slows, the industry is shifting to system-level innovation through advanced packaging. Discover the critical differences between 2.5D and 3D IC architectures and why they're revolutionizing semiconductor design.

As traditional silicon scaling approaches its physical limits, the semiconductor industry is pioneering new approaches to continue performance improvements. Advanced packaging technologies, particularly 2.5D and 3D integrated circuits, represent the next frontier in semiconductor innovation—moving beyond Moore's Law through clever integration rather than just smaller transistors.

These technologies aren't just academic concepts—they're powering today's most advanced processors, from AMD's chiplet-based CPUs to Apple's M-series processors. Understanding the differences between 2.5D and 3D integration is crucial for anyone involved in modern semiconductor design.

2.5D ICs: Horizontal Integration Revolution

The City Analogy

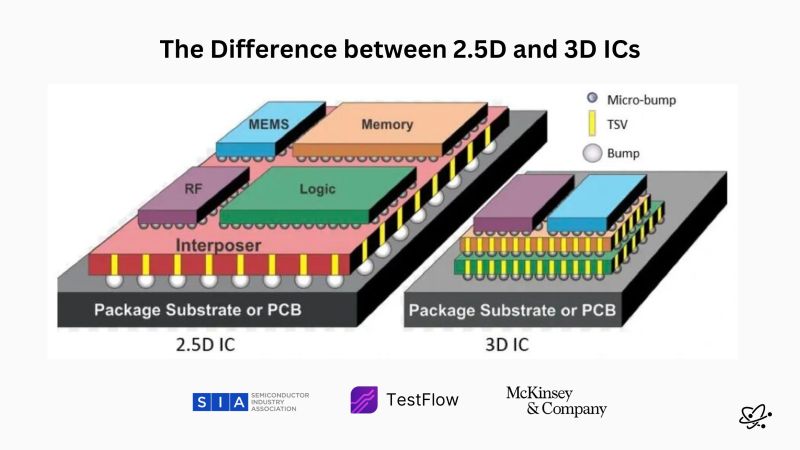

Think of 2.5D ICs as a city spread across one giant floor—multiple buildings (chips) connected by high-speed roads (interposer traces). Chips are placed side-by-side on a common interposer (silicon or glass), which routes connections between them with much higher bandwidth and lower latency than traditional PCBs.

Key Characteristics

- • Chips mounted side-by-side on interposer

- • Silicon or glass interposer substrate

- • High-density interconnect routing

- • Shorter interconnect lengths than PCB

- • Heterogeneous chip integration

- • Known good die (KGD) requirement

Technical Advantages

- • 10-100x higher interconnect density

- • Reduced parasitic capacitance

- • Lower power consumption

- • Better signal integrity

- • Improved thermal management

- • Mix different process technologies

2.5D Implementation Examples

AMD Ryzen/EPYC

Chiplet architecture with I/O die and compute chiplets

Xilinx FPGAs

FPGA fabric with HBM memory stacks

NVIDIA AI GPUs

GPU dies with HBM memory integration

3D ICs: Vertical Integration Breakthrough

The Skyscraper Analogy

3D ICs are like skyscrapers—floors (chips) stacked vertically with elevators (Through-Silicon Vias or TSVs) moving data between layers. This approach offers the ultimate in density and performance but presents significant thermal and manufacturing challenges.

Core Technologies

- • TSVs: Vertical connections through silicon

- • Wafer Bonding: Direct wafer-to-wafer attachment

- • Thinning: Ultra-thin wafer processing

- • Alignment: Precise layer-to-layer registration

- • Testing: Layer-by-layer validation

Performance Benefits

- • Shortest possible interconnect lengths

- • Maximum integration density

- • Reduced power consumption

- • Fastest inter-chip communication

- • Smallest form factor

3D IC Implementation Examples

Intel Foveros

3D chiplet integration with active interposer

Samsung HBM

Stacked memory with TSV connections

Apple M-Series

Unified memory architecture with 3D elements

2.5D vs 3D: Head-to-Head Comparison

Comprehensive Comparison Matrix

| Aspect | 2.5D ICs | 3D ICs |

|---|---|---|

| Integration Density | High | Very High |

| Interconnect Length | Short | Shortest |

| Thermal Management | Good | Challenging |

| Manufacturing Complexity | Medium | High |

| Cost | Medium | High |

| Testing Complexity | Medium | Very High |

| Yield Impact | Low | Medium |

| Market Maturity | Production Ready | Emerging |

Technical Implementation Details

2.5D Interposer Technology

Silicon Interposer

- • High-density routing layers (10-12 metal layers)

- • Fine-pitch interconnects (2-5 μm)

- • Through-silicon vias for power/ground

- • Excellent electrical performance

- • Compatible with standard processes

Glass Interposer

- • Lower cost than silicon

- • Better thermal properties

- • Larger panel sizes possible

- • Lower electrical losses

- • Emerging technology option

3D IC Through-Silicon Via (TSV) Technology

TSV Specifications

- • Diameter: 5-100 μm typical

- • Aspect ratio: 5:1 to 20:1

- • Pitch: 10-200 μm spacing

- • Materials: Copper, tungsten

- • Insulation: SiO2, Si3N4

Manufacturing Process

- • Via etching (DRIE or laser drilling)

- • Insulation layer deposition

- • Metallization and planarization

- • Wafer thinning to 25-100 μm

- • Wafer-to-wafer bonding

Real-World Applications and Use Cases

2.5D Applications in Production

High-Performance Computing

AMD GPUs

Radeon RX 7000 series with chiplet design

Xilinx FPGAs

Versal and Kintex series with HBM integration

Intel Ponte Vecchio

Data center GPU with multiple chiplets

AI Accelerators

NVIDIA H100

GPU with HBM3 memory integration

Google TPU v4

AI training chips with HBM2

AMD Instinct MI300

CPU+GPU+HBM integration

3D Applications: Leading the Future

Memory Integration

Samsung HBM Stacks

8-12 DRAM layers with TSV connections

SK Hynix HBM3E

Advanced 3D memory for AI applications

Micron HBM3

High-bandwidth memory stacks

Logic Stacking

Intel Foveros

Heterogeneous 3D integration

Apple M-Series

Unified memory and processing integration

TSMC SoIC

System-on-Integrated-Chips platform

Challenges and Engineering Solutions

Major Challenges

Thermal Management

3D stacking concentrates heat, requiring advanced cooling solutions

Testing Complexity

Layer-by-layer testing and debug access limitations

Manufacturing Yield

Compound yield effects and known good die requirements

Design Complexity

Multi-layer routing, power delivery, and signal integrity

Engineering Solutions

Advanced Thermal Design

Micro-cooling channels, thermal TSVs, and heat spreading

Built-in Test Structures

Embedded test circuits and scan chain accessibility

Known Good Die Testing

Pre-integration validation and redundancy planning

Advanced EDA Tools

3D-aware design tools and thermal simulation

Validation Strategies

2.5D Validation

- • Individual chiplet testing before assembly

- • Interposer electrical verification

- • System-level integration testing

- • Thermal characterization

3D Validation

- • Layer-by-layer testing during assembly

- • TSV electrical and mechanical testing

- • Thermal stress validation

- • Limited access debug strategies

Market Adoption and Industry Trends

Current Market Status

2.5D Market

3D Market

Future Projections (2025-2030)

Combined 2.5D/3D market by 2030

Of high-performance chips using advanced packaging

Expected to grow faster than 2.5D

Advanced Packaging Validation Requirements

Complex Testing Scenarios

2.5D and 3D ICs introduce new testing challenges that require specialized equipment, methodologies, and expertise to ensure reliable operation across all conditions.

Testing Challenges

- • Limited physical access for probing

- • Complex failure mode analysis

- • Thermal cycling stress testing

- • Inter-layer communication verification

- • Power delivery network validation

- • Signal integrity across interfaces

Advanced Solutions

- • Built-in self-test (BIST) circuits

- • Non-invasive testing techniques

- • AI-driven test pattern generation

- • Multi-site parallel testing

- • Advanced thermal imaging

- • Machine learning failure prediction

TestFlow for Advanced Packaging Validation

2.5D and 3D ICs require specialized validation approaches that can handle their unique architectures and integration challenges. TestFlow's AI-powered platform provides comprehensive testing capabilities for advanced packaging technologies, ensuring reliable operation of complex integrated systems.

Learn About Advanced Packaging TestingBeyond Moore's Law: The Integration Revolution

2.5D and 3D integration technologies represent the semiconductor industry's response to the slowing of traditional scaling. Rather than waiting for smaller transistors, these approaches achieve performance improvements through intelligent system architecture and advanced packaging techniques.

The choice between 2.5D and 3D integration depends on specific application requirements, cost constraints, and performance targets. 2.5D offers a more mature, cost-effective solution for many applications, while 3D provides the ultimate in integration density for applications that can justify the additional complexity and cost.

As these technologies mature and costs decrease, we'll see broader adoption across more market segments. The future of semiconductor performance lies not just in smaller transistors, but in smarter integration—and both 2.5D and 3D approaches will play crucial roles in that future.

Navigate Advanced Packaging Complexity

Whether you're implementing 2.5D interposer designs or 3D stacked architectures, comprehensive validation ensures your advanced packaging solutions deliver the expected performance and reliability benefits.