Post-Silicon Validation Automation That Delivers Results

Replace LabVIEW, Python, and Every Other Tool with One Simple AI Platform

Before TestFlow

After TestFlow

Stop Spending Weeks on Manual Validation

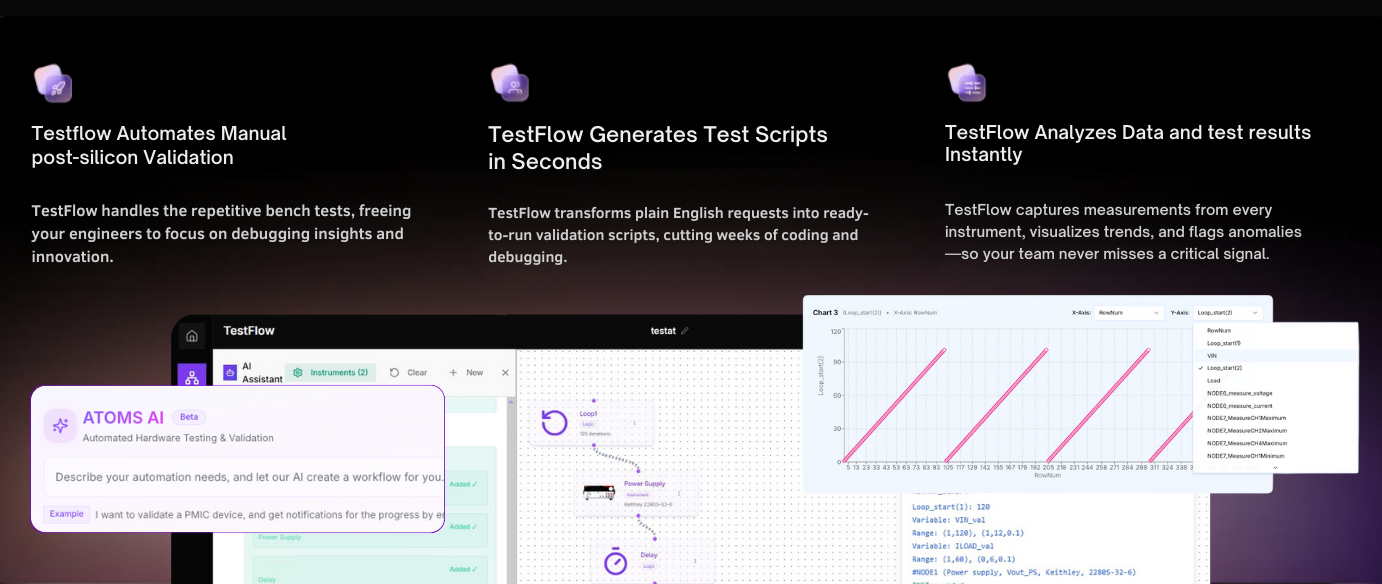

See how AI automation transforms the three most time-consuming tasks in post-silicon validation workflows.

AI Script Generation

Transform datasheet specifications into production-ready test scripts automatically. Upload your datasheet, describe requirements, and get comprehensive validation code in minutes.

Automated Test Planning

Generate comprehensive test plans from datasheet specifications. AI analyzes your chip requirements and creates detailed validation sequences with optimal test coverage.

Real-time Analytics

Monitor validation progress with live analytics dashboards. Get instant pass/fail determinations, automated compliance checking, and detailed performance insights.

200+ validation engineers are saving 70% of their validation time

Used by validation teams at leading semiconductor companies worldwide

Free 30-day trial • Full platform access • No credit card required • Setup in 5 minutes

Validate Chips Using Human Language

Simply describe what you want to test in plain English, and our AI will automatically create and execute the validation workflow

Natural Language Processing

Express complex validation requirements in simple English, no programming knowledge needed. Our AI understands context and technical nuances.

Intelligent Automation

AI automatically creates test sequences, configures instruments, and generates comprehensive reports. Watch your workflows come to life instantly.

Connect Your Lab Instruments

Seamlessly connect your existing test equipment and lab instruments to TestFlow. Our universal compatibility ensures integration with leading hardware validation tools.

Ask AI for Your Validation Requirements

Describe your chip validation needs in natural language. TestFlow's AI understands your requirements and automatically configures the optimal testing parameters and protocols.

Get the Generated Test Script

TestFlow automatically generates comprehensive test scripts based on your requirements. Review, customize, and approve the validation sequence before execution.

Start Executing the Validation

Execute your PMIC validation tests with real-time monitoring and progress tracking. TestFlow manages the entire process automatically while you monitor the results.

PMIC Analytics and Generate Report

Comprehensive PMIC data analysis with automated report generation. Get detailed V/I sweep results, load regulation analysis, and compliance verification.

Works with Leading Test Equipment

Seamlessly integrate with industry-standard instruments from top manufacturers. Plug & play compatibility with automatic device detection.

200+ instruments supported and counting

Don't see your equipment? We're constantly expanding compatibility.

Ready to transform your validation process?